Applications

A.D. Tubi Inossidabili is highly specialized in the production of welded tubes for heat transfer applications, particularly within the energy and process industries: space heating, refrigeration, air conditioning, power stations, chemical and petrochemical plants, petroleum refineries, natural-gas processing, waste water treatment, desalination plants, nuclear power stations, solar energy plants. Both straight and low stress U-tubes can be supplied, typically for: Condensers, Feedwater Heaters and Shell & Tube Heat Exchangers.

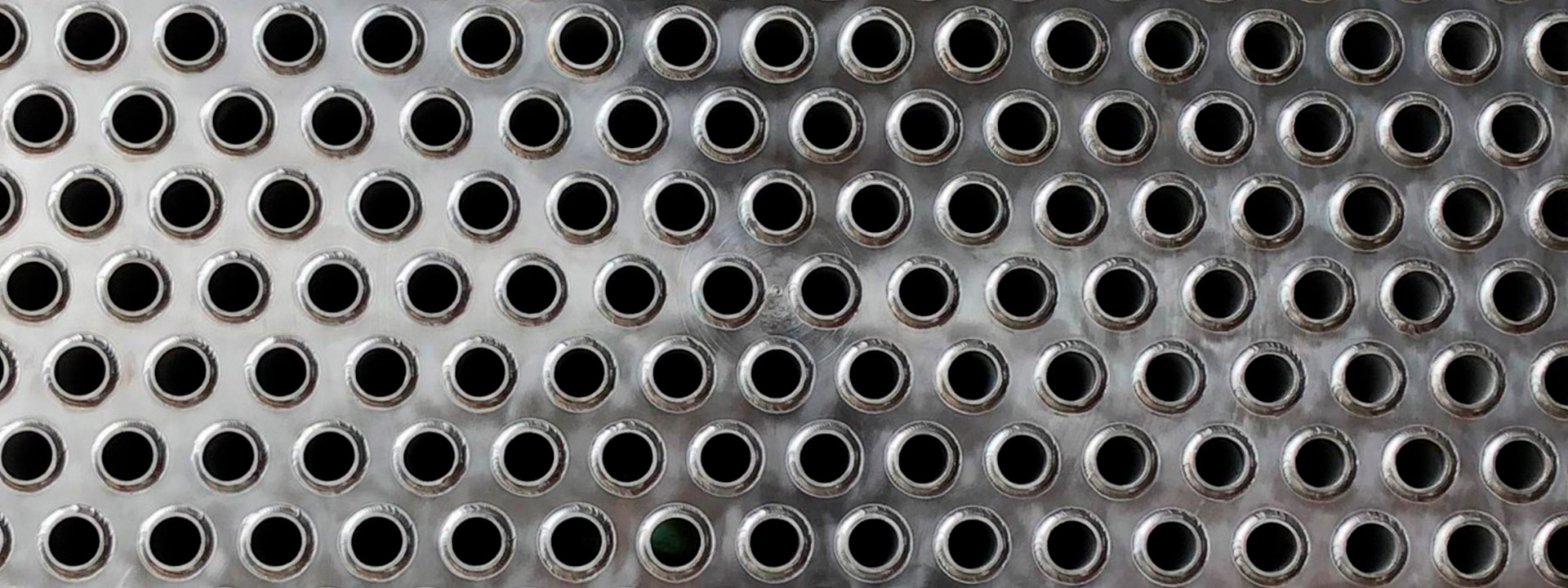

CONDENSERS

Surface condensers are water-cooled Shell & Tube heat exchangers installed on the exhaust steam from a steam turbine in thermal power stations. They convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure.

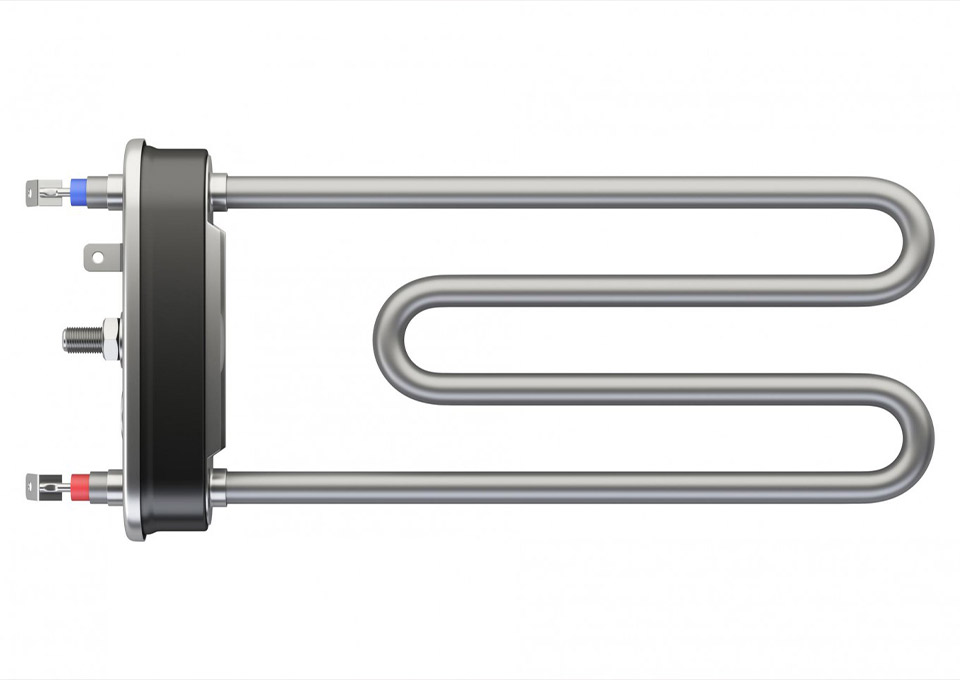

FEEDWATER HEATERS

U-bent low stress tubing Feedwater Heaters are used in power-plant to pre-heat the water delivered to a steam generating boiler, improving the thermodynamic efficiency of the system.

SHELL & TUBE HEAT EXCHANGERS

Shell & Tube Heat Exchanger is a general term referring to components transferring heat

between two or more fluids. They can be used to both cool and heat large scale industrial

processes and their design varies depending on the type of fluids, phases, temperature, density, viscosity, pressure, chemical composition and other thermodynamic properties.

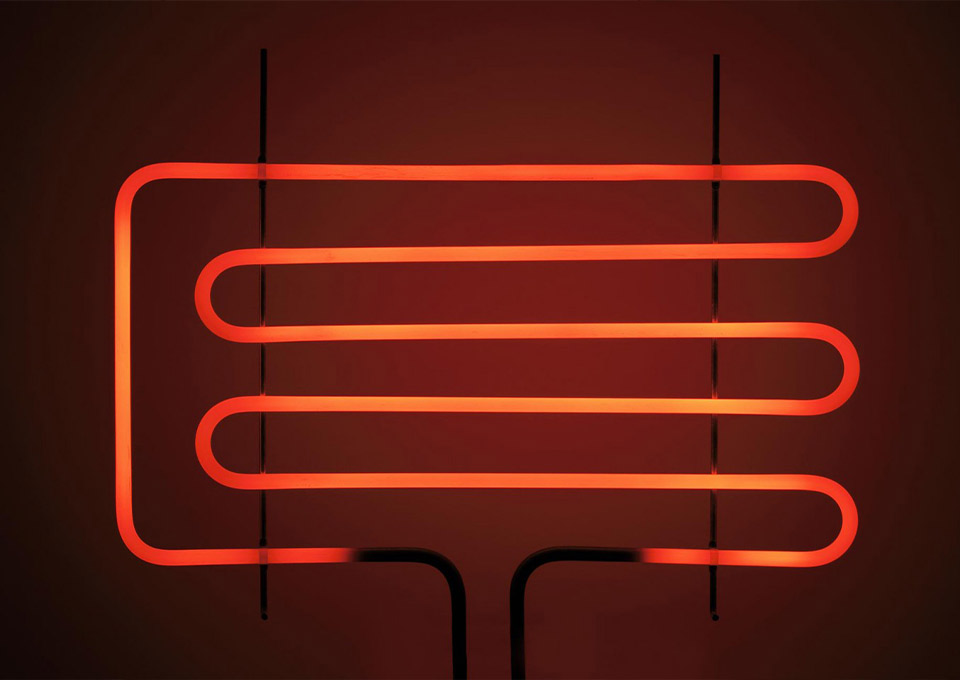

HEATING ELEMENTS

Tubular Heating Elements are used to heat water or other liquids by converting electrical energy into heat. They can be straight or bent to a shape to span an area to be heated.

EVAPORATORS

Evaporators are used for converting liquid into vapour. The single-effect evaporator consists of a container or surface and a heating unit; the multiple-effect evaporator uses the vapour produced in one unit to heat a succeeding unit. Some evaporators are used to concentrate a solution by vapourizing and eliminating water, as, for example, in a concentration plant for sugar and syrup. In purification processes, such as the desalination of seawater, evaporators convert the water to vapour, leaving mineral residues in the evaporator. The vapour then is condensed into (desalinated) water. In a refrigeration system, the cooling effect is produced as the rapid evaporation of the liquid refrigerant absorbs heat.